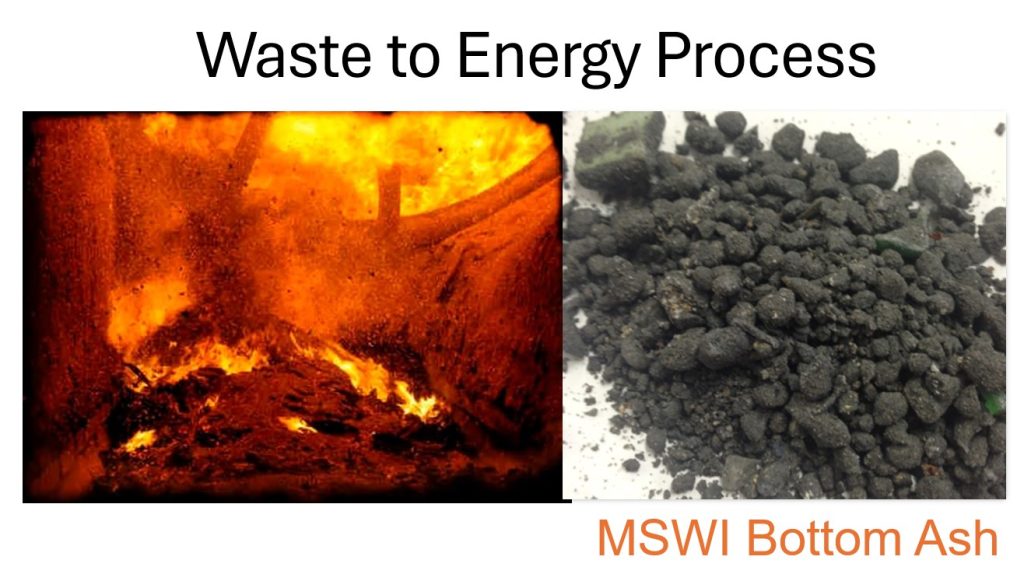

Given the similar physical properties to conventional aggregates, municipal solid waste incineration (MSWI) bottom ash (BA) has the potential to be an effective and sustainable alternative aggregate in portland cement concrete. The use of MSWI BA as an aggregate in concrete can reduce landfilling, immobilize hazardous chemical species, and ease market strains on naturally-mined aggregates. However, the presence of metallic aluminum impedes large-scale use of MSWI BA in concrete construction. Metallic aluminum present in MSWI BA generates hydrogen gas within alkaline concrete pore solutions during and after setting. Hydrogen gas entraps large air voids before setting and exerts expansive stress and cracks in the surrounding hardened cementitious matrix after setting. Moreover, metallic aluminum is inherently difficult to remove from MSWI BA through manual sorting or eddy current separation especially when particle sizes are small. Metallic aluminum also undergoes significant thermal conversion during incineration, recombining in quench products and alloying with other metals which further make it difficult to remove. Past research has found that blending MSWI BA with conventional aggregates can be effective for concrete used in limited, non-structural applications. However, to increase throughput and thus thereby enhance the economics of recycling BA in construction, the issue of metallic aluminum needs to be addressed.

This project is sponsored by the The William W. “Bill” Hinkley Center for Solid and Hazardous Waste Management which coordinates the State of Florida’s solid and hazardous waste research program. The center is funding this project which aims to create practical and economical washing-based pretreatment processes to improve the performance of MSWI BA as a concrete aggregate. Deactivating the reactivity of metallic aluminum in BA through washing or soaking may be more effective and feasible than further reducing aluminum content via complex separation technologies.

Our TAG Committee

- Joseph Kilsheimer, Florida Waste-to-Energy Coalition

- Jason Gorrie, JMG Engineering

- Kevin Pliska, Covanta / Pasco County

- Ramana Kari, Palm Beach County SWA

- Chris Eckert, Hillsborough County

- Diep Tu, Florida Prestressed Concrete Association

- H.D. Deford, Florida Department of Transportation

- Jeff OLeary, Consultant (Formerly Argos/Florida Rock)

- Jose Manuel Dominguez Ruano, Cemex

- Ryan Betz, Argos / Summit

- Steve Bossotti, Advanced Recycling Technologies

- Marc Rogoff, Geosyntec Consultants